6.4. Linear Actuators#

Linear actuators are devices that convert energy into straight-line motion. They are used everywhere in mechatronics, from simple solenoids that give a quick push, to precision screw-driven mechanisms that slowly and accurately move a load. While some linear actuators directly create linear force, many actually work by converting the rotation of a motor into linear motion through clever mechanical linkages.

6.4.1. Solenoids#

Solenoids are the simplest linear actuators. They are made of a coil of wire with a movable iron plunger inside. When electric current flows through the coil, it creates a magnetic field that pulls the plunger into the coil. When the current stops, a spring pushes the plunger back out.

Solenoids act like electromagnetic push-pins. They only move while powered, and the motion is fast but short. They are usually controlled simply by switching the current on and off using a transistor or relay.

Advantages

Very fast response

Simple on/off control

Strong short bursts of force

Examples

Electric door locks

Pinball machine launchers

Opening and closing fluid valves

Motor-Driven Linear Actuators

6.4.2. Motor-Driven Linear Actuators#

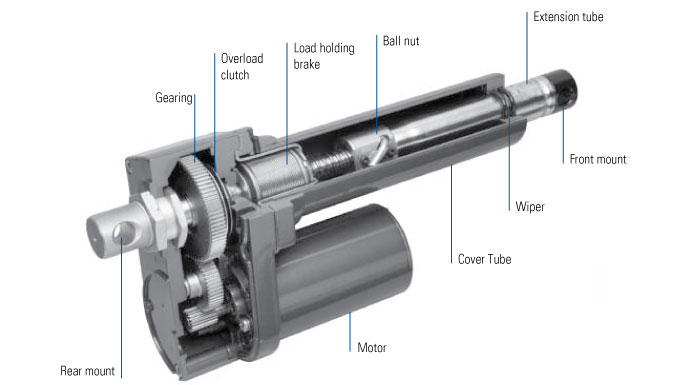

Image from https://www.thomsonlinear.com/#

Some linear actuators use a rotating motor to produce linear motion. They usually contain a leadscrew or ballscrew: when the motor spins the screw, a nut moves along its length, converting the rotation into smooth, controlled linear travel.

Because the motor can spin continuously in either direction, these actuators can move forward or backward as far as the screw allows. The position can be controlled precisely by counting the motor’s rotations, especially when combined with a stepper motor or encoder feedback. Motor-driven linear actuators are slower than solenoids, but much more precise and can move heavy loads over long distances.

Advantages

Precise, controllable motion

Can move heavy loads

Can travel long distances

Examples

3D printer axes driven by stepper motors and leadscrews

Adjustable lifting platforms

Motorised camera sliders

6.4.3. Rotary Motion to Linear Motion#

Many types of linear movement in machines are actually produced by converting rotary motion into linear motion. This is done with mechanical linkages that change spinning into sliding.

Some common conversion mechanisms include:

Leadscrews and ballscrews: As described above, spinning the screw moves a nut along its length. This is one of the most precise and controllable methods.

Rack and pinion: A spinning gear (pinion) pushes against a straight toothed bar (rack), making it slide.

Cams: An off-centre rotating disk (cam) pushes a follower up and down as it spins, producing periodic linear motion.

Crank-slider: Like in a car engine, a rotating crank turns the back-and-forth sliding of a piston.

These mechanisms let designers take advantage of the speed and efficiency of motors while producing the linear movement needed for many tasks.